Print

Categories New Machines Heavy gauge machines PK-Serie

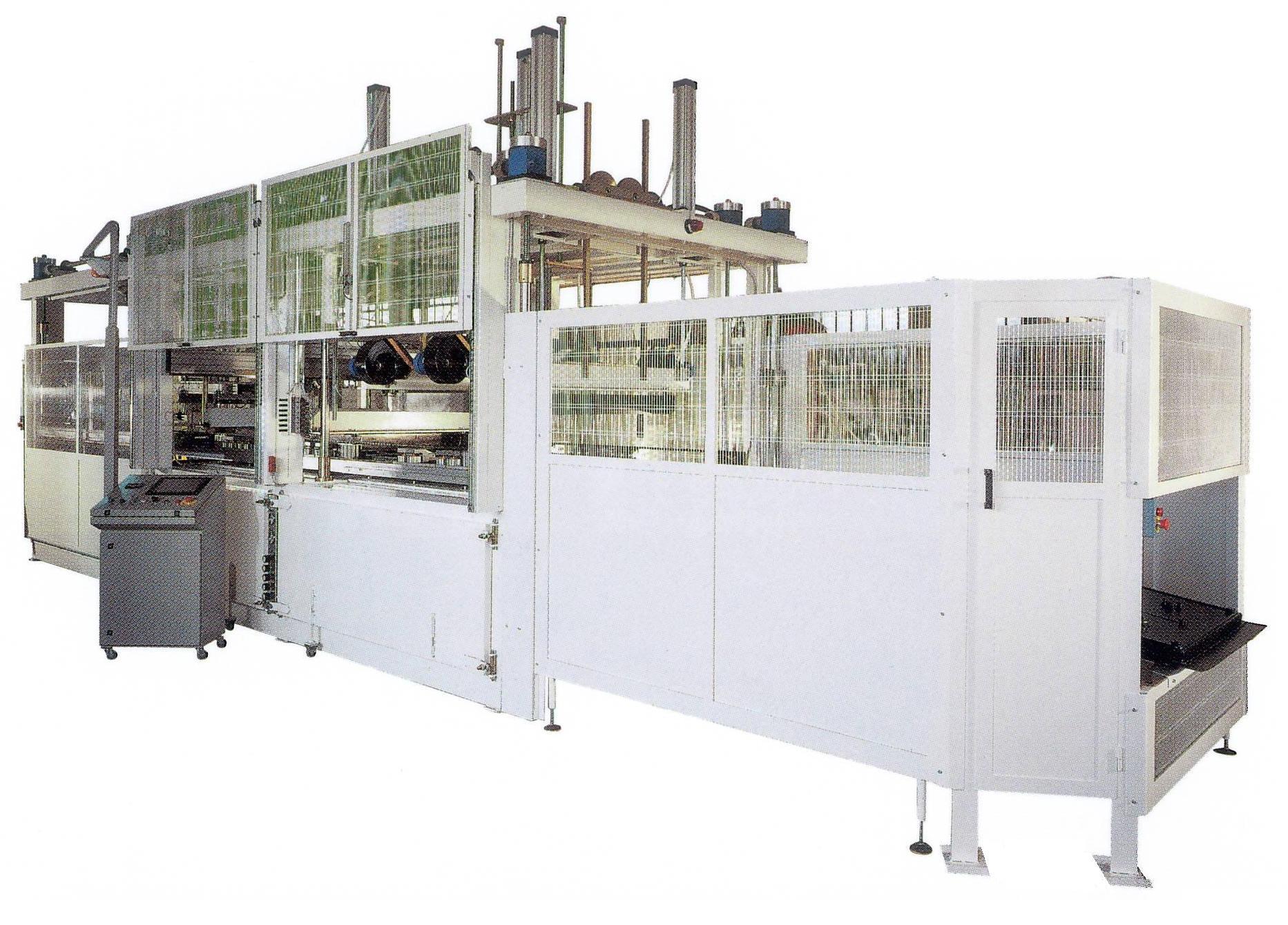

PK Series: Automatic Cycle Heavy Gauge machines

The PK series is an automatic heavy gauge thermoforming machine. The sheet is automatically feed by using a pick up system and the thermoformed parts is discharge at the end of cycle automatically. There is no handling needed by the operator.

The advantages

- Productivity with a 5 mm ABS sheet thickness: 55 cycles / hour.

- Quick setup

- Thermoforming station is enclosed in a pressure box to allow sheet sag control while in heating process.

- Different heating ovens configurations for greater energy saving.

- Working clamping window adjustable by motors.

- Accept thick material sheet.

- Low maintenance.

The features

- Automatic sheet feeding: System that support the pallets with two stations that allow vacuum cups to pick up the sheets. It also accept loading even if the pallet is not position perfectly straight. It is moving to the next pallet when the first is empty.

- Sheet index transport done by clamping chains that allow material thickness from 1 to 11 mm without any adjustments to the system.

- Heating done by single or optional double heating platen. Heaters are made out of ceramic and are design for energy saving. Zones are controlled individually for a better heating process.

- Heater pyrometrics reading sensor both for heating temperatures and/or for cooling fan controls.

- Mold platen movements activated by pneumatic, hydraulic or servomotors system.

- Web clamping movements activated by pneumatic, hydraulic or with servomotor systems.

- Plug assist movements activated by pneumatic, hydraulic or with servomotor systems.

- Machine is equipped with servo valves that are controlling Vacuum , sheet support through heating cycle, material bellow through forming phase and finally release of product at the end of cycle.

- Material cooling is provided by high speed cooling fans with an optional spray system to increase the thermoformed part cooling speed.

- Fast lock tool on the mold platen (optional)

- All adjustments are made from the touch screen for easier and faster parameters changes.

- Color touch screen to make parameter adjustments and supervise the thermoforming process.

- Recipe memory system to do faster tool changeover Recall or save parameters in a matter of a few seconds.

- Compact flash card memory backup.

- Internet ready to allow our technicians to diagnose or supervise any aspect of the system.

| Model PK | 96 | 150 | 195 | 240 |

| Max working size (frontal side*large) (mm)* | 1200x800 | 1500x1000 | 1600x1300 | 2000x1200 |

| Max. up deep drawing (mm)* | 500 | 500 | 600 | 600 |

| Max. down deep drawing(mm)* | 300 | 300 | 300 | 300 |

*Working size and mold depth customized under request.

PK Series: Automatic Cycle Heavy Gauge machines - Mega Plast GmbH