Categories New Machines Thin gauge machines FDC-PVDDC

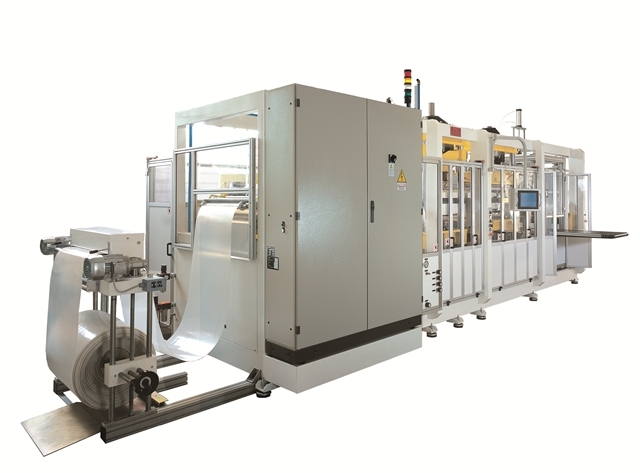

FDC-PVDDC

This automatic thermoforming machine is ideal for producing thermoformed parts in medium to large volumes . This use the advantage of electrical movements contained different and unique characteristics. The main topic of these models is the cutting phase that can be done in the mold, ensuring maximal precision in relation to the material shrinking. Can be supply two kinds of configurations FDC and PVDDC model; while the FDC has only one press in which the parts are formed and cut, the PVDDC is equipped with two presses that give the possibility to work in forming and die cutting in the mold or forming and cut the parts in a second press (same philosophy of RVE and PVE).

The advantages

- Electrical system with servomotors: greater reliability, high productivity, constant speed,higher thermoformed quality, adjustable depth mold.

- Energy Saving up to 60%.

- Easly reversibilty of vacuum/air pressure from the touch screen.

- Toogle movements systems.

- Upward and downward stacking all in one universal stacker.

- Vacuum cups and additional module for difficult stacking parts.

- Fast tool locks.

The features

- Unwind auto-lifting roll trolley system for a quickly and simple setup.

- Film index with double pin chain driven by servomotor. Optional offset system option to work with printed film.

- Pre-heat system that allow to heat the two lateral edges of the material to accommodate thicker and harder material production capabilities.

- Double heating platen system with individual zone control, to control every part of the heating process.

- Four colons forming station table with tables driven by toggles and servomotors. This press can form and cut all in one tool.

- Plug assist or third motion system on both forming tables control individually by servomotors for a better material distribution.

- Fast tools lock for quick mold change, easier and faster maintenance schedule.

- Four colons trim press with tables driven by toggles and servomotors.

- Up & down stacking from the same universal stacker. Output of products by driven conveyors. A & B stacking supplied on the standard stacker.

- Optional vacuum cups robots modules for A & B stacking and pick up of difficult parts.

- Optional horizontal stacking module for lids and round parts that need to be inserted in bags.

- Station positions controlled by actuators and encoders.

- Scrap wrapping device with constant tension and safety clutch. Extraction is made by pneumatic system.

- Optional inline grinding system.

- Punching press can be supplied in all configurations, both inline for holes, slots or outside the product. Everything with integrated stacking vertical or horizontal.

- Optional preheating roller module for material like polypropylene.

- Optional inline extruder to feed directly the thermoformer.

- Optional labelling machine for any type of label with adhesive or paper.

- All adjustments are made from the touch screen for easier and faster parameters change.

- Color touch screen to make parameter adjustment and supervise the thermoforming process.

- Recipe memory system to do faster tool changeover. Recall or save parameters in a matter of a few seconds.

- Compact flash card memory backup.

- Internet ready to allow OMG technicians to diagnose or supervise any aspect of the system.

| Model FDC / PVDDC | 16 | 18 | 24 | 33 | 42 | 52 | 52B | 58 | 58B | 64 | 72 | 72B |

| Max working size (width*index) (mm)* | 400x400 | 500x350 | 600x400 | 600x550 | 650x650 | 800x650 | 650x800 | 900x650 | 650x900 | 800x800 | 900x800 | 800x900 |

| Max lower strokes tables (mm)* | 120 | 120 | 120 | 120 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Max upper strokes tables (mm)* | 120 | 120 | 120 | 120 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

*Working size and depth customized under request.